With the scarcity of energy, energy conservation has attracted more and more attention. How to do a good job in energy conservation of equipment has become an important topic in the industry.According to statistics, a DN200 bare valve (valve meter temperature 180℃) loses heat equivalent to 4,000 yuan (natural gas). After the valve is insulated, the surface temperature is reduced to about 40℃, which effectively reduces heat loss.There are thousands of valves on enterprise equipment pipelines, which can greatly reduce the energy consumption ratio of enterprises after heat preservation and energy saving, and bring direct economic benefits to enterprises.

1. Energy-saving shell structure composition

The energy-saving shell produced by our company is composed of imported high-temperature resistant, fire-resistant and thermal insulation materials, oil thermal insulation layer and protective layer.Designed according to the specific shape of the equipment, the protective layer is divided into two forms according to the material: 1. Soft material shell; 2. Hard material shell. Suitable for different working conditions.

2. Performance Parameters

1. Excellent thermal insulation performance, thermal conductivity: 0.035-0.048W/M.K (under normal temperature);

2. Perfect chemical stability, resistance to various chemical corrosion, anti-moth and anti-fog;

3. Good high temperature resistance (high temperature 600-800℃), maximum 2000℃ resistance, fire retardant, aging resistance, adapt to various weather conditions, and have good waterproof performance.

3. Advantages and Features

1. The effect of heat preservation and energy saving is excellent. A lot of practice has proved that the energy saving effect can reach about 35%-40% under normal circumstances;

2. Easy to install and disassemble, convenient for maintenance. When the equipment is overhauled, it can be partially disassembled without delaying production time;

3. Improve the working environment, reduce the humidity of the working environment, and prevent staff from scalding;

4. It can be tailored according to different shapes of equipment, suitable for feed, food, petrochemical, metallurgy, paper making, electric power and other industries. Its materials are special, with good thermal insulation, good performance, long service life, and can be greatly improved utilization rate and lower maintenance cost;

5. Good toughness, easy to bend and connect;

6. No asbestos, no dust pollution during disassembly and installation, harmless to the human body, and meets the environmental protection requirements of modern enterprises.

7. The appearance of the product is clean and tidy, the surface does not stick to water, oil, moisture, and easy to clean and scrub;

8. Low cost. Compared with traditional pipeline insulation, the cost is greatly saved. The secondary utilization rate of traditional pipeline insulation is almost zero, and our company's insulation materials can be used multiple times.There will be no equipment relocation that the insulation layer is damaged and cannot be used. Energy-saving shells greatly bridge the unavailable gap, thereby realizing cost-efficient savings.

4.Application

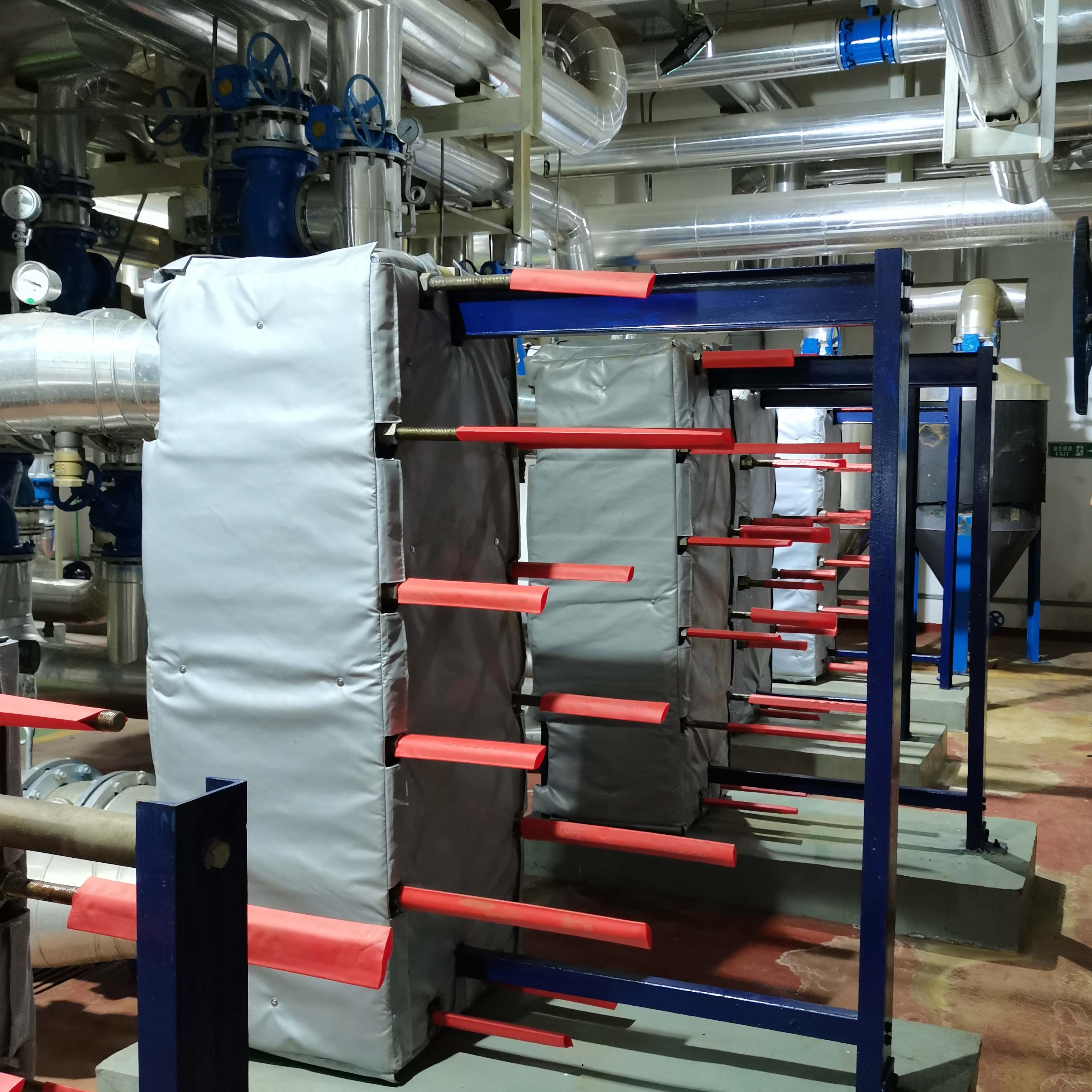

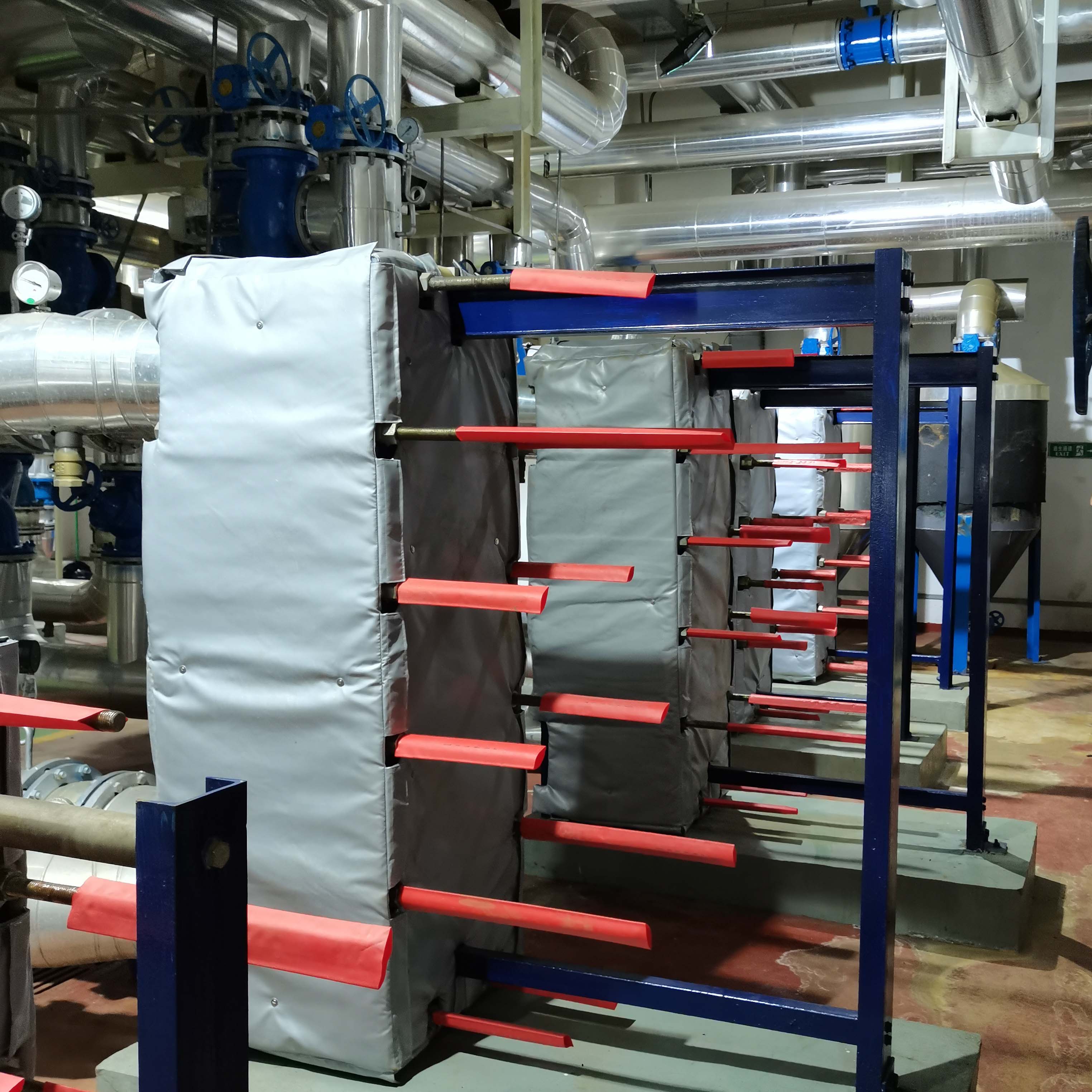

Energy-saving shells are currently the preferred components for valves, heat exchangers, and high-temperature equipment. It is widely used in thermal equipment and various heating equipment in dairy, food, medicine, petrochemical, metallurgy, electric power, textile, tobacco, beer, construction and other fields. It is suitable for heat insulation of various pipeline equipment and is an ideal heat preservation and energy saving material.

Energy-saving shell

Energy-saving shell